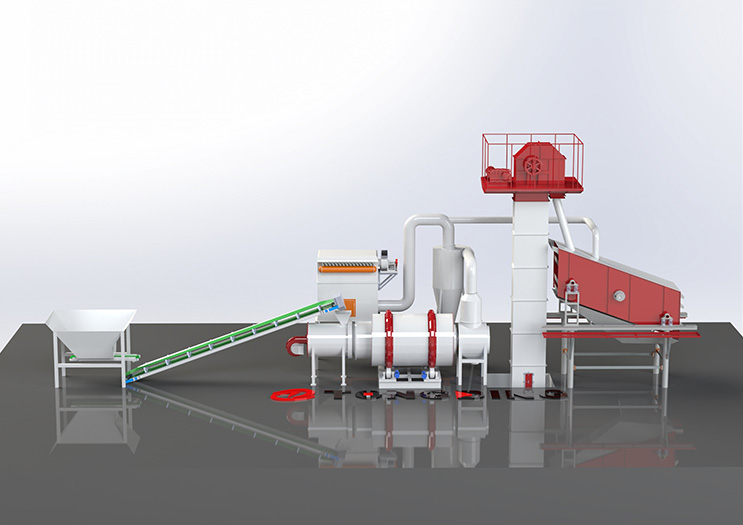

Capacity: 5-120 T/H

Drying → Collecting Dust → Screening

Drying: Through disk feeder and wet sand belt conveyor, feed wet sand from moist-material bin to rotary dryer for drying, heated by gas combustion chamber.

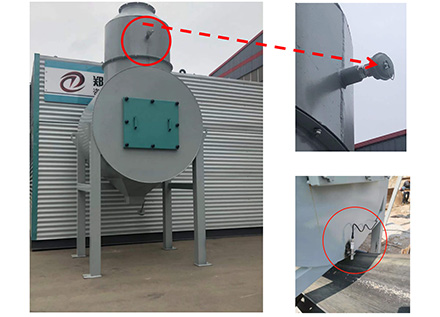

Collecting Dust: The dust producing in the process of drying will be collected by dust removal system and cyclone dust collector, fall down to the dry sand belt conveyor. The dry sand will be delivered to the linear vibrating screen for screening.

Screening: The dry sand conveyed by dry sand bet conveyor is screened into different size of sand according to customer’s requires.

E-mail :

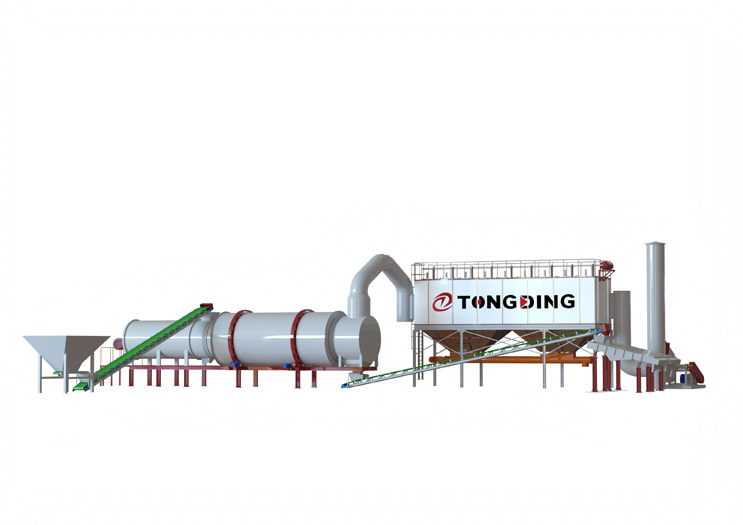

info@tongdingmachinery.comMaterials is sent into stock bin by belt conveyor or bucket elevator, then conveyed from material silo to belt conveyor by disk feeder, belt conveyor carry materials into feed pipe. The gradient of newest energy-saving feed pipe must be larger than materials’ angle of crater in order that materials flow into dryer successfully. The drum of dryer is a rotary drum which is slightly at an angle with the horizontal line. Materials get in dryer from one side, heat carrier follows at the same time. Through the inner cylinder, middle cylinder, outer cylinder, arrive at discharging port, finally get into discharging silo. After heat carrier goes through dryer, materials carried in heat need cyclone dust collector to capture down. If a need to further reduce the dust content, it should go through bag filter or wet dust collector before discharging. Finally linear vibrating screen separates the qualified finished products from the dried material.

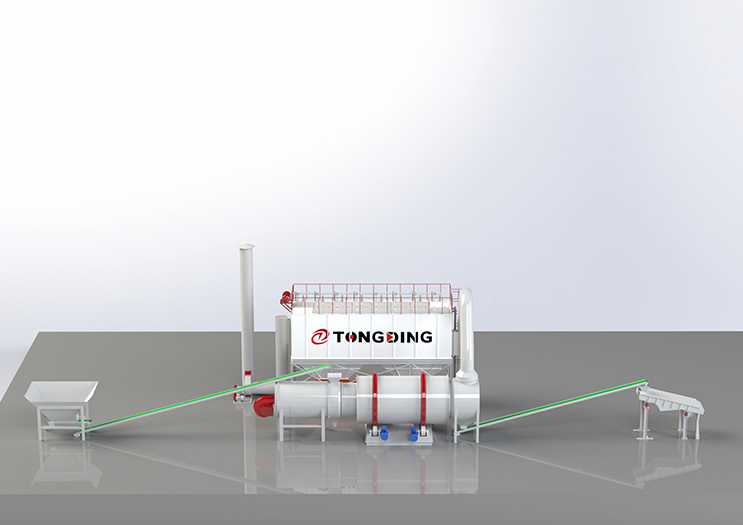

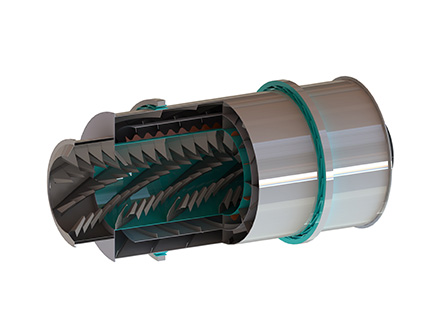

Triple Pass Rotary Dryer has 3 drying zones in the 3 cylinders (internal one, middle one and external one) which construct the rotating body. Heat processing of a product with high moisture content is done efficiently in those 3 drying zones. The product is put in from the inlet of the hopper, sent to the internal cylinder where heating of the product is evaporation of moisture is promoted further. The solid constituent of the product is gradually broken into piecesand discharged from the outlet via the third final drying zone. The hot air produced in the furnace is sent to the internal cylinder, passes through the middle and external cylinders. The hot air is then sent to the cyclone where dust is removed.

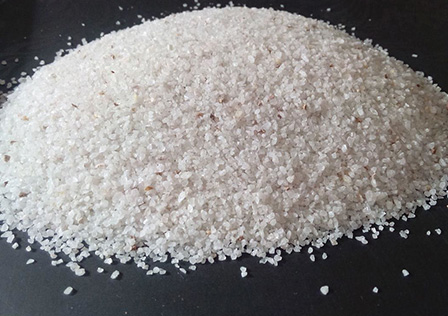

Foundry sand, Quartz sand, Garnet sand, Emery, Kuala kangsar, Sand, River sand, Sea sand, Frac sand, Casting sand, Gold and steel sand, Optical sand, Sheet sand, Glass sand, Photovoltaic sand, Tail sand, Mechanical sand, Glass bottle, Flat glass, Fluorite powder, Iron powder, Carbon black, Lepidolite, Muscovite, Tungsten and molybdenum powder, Potassium, albite powder, Granite powder, Marble powder, Slag, Water slag, Activated carbon, Charcoal, Coal, The cat litter, Chinese medicine residue, Coal gangue, Industrial salt, Iron filings, Huanglin tailing

Facturing Sand

Glass Sand

Iron Powder

Quartz Sand

Titanium Powder

Machine-made Sand

Slag

Stone Powder

River Sand

| Model | Power (kw) | Capacity (T/H) | Highest Temp(℃) | Outlet Temp(℃) | Rotary Speed (r/min) | Installation Angle | Final Moisture | Heat supply mode |

| TDS 623 |

4 | 3-5 | 800 | <60 | 9 | Aclinic | ≤0.5% |

1) Firewood

|

| TDS 625 |

4 | 5-8 | ||||||

| TDS 6215 |

7.5 | 10-20 | ||||||

| TDS 6230 |

5.5*4 | 30-40 | 7 | |||||

| TDS 6260 |

11*4 | 60 | ||||||

| TDS6100 | 15*4 | 100-110 | 1)Firewood 2)Pulverized coal 3)Diesel 4)Natural gas 5) fuel oil |

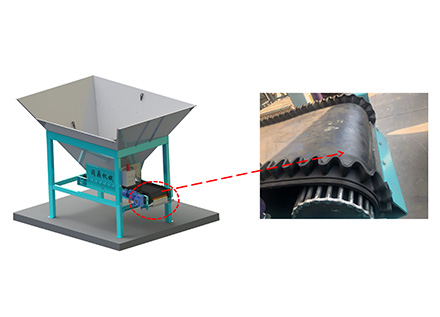

Store wet materials.

Special design of silo, enable no remaining material at four corners. Equip with belt feeder.

Convey materials.

High temperature resistance. Moisture proofing. Rubbing resistance.

Programmable logic controller, Ignition transformer, Servo motor, Wind pressure switch, ow pressure switch and magnetic valve.

Provide heat to dryer. Internal by refractory brick laying.

Dry wet materials comprehensively.

High wear resistance. Widen running belt to increase the stability abd extent service life. Running belt excursion by applying our patented technology. Water tank under the frame, reducing the heat and resist skid.

Reduce the air loss of the induced air system and increase the drying output. Precisely monitor and control the materials temperature and effectively take advantage of heat.

Collect dust more effectively.

Separation of impurities, such as the soil in the finished sand.

Convey materials.

High temperature resistance. Moisture proofing. Rubbing resistance.

Screen material to different sizes.

Install special motor(export-oriented motor) from Xinxiang motor factory. Effectively screen out qualified materials.

Don't Hesitate Contact Us For Better Help & Services

E-mail :

info@tongdingmachinery.comTel / Whatsapp / Wechat :

+86 13673306161Fax :

+86 0371 63715718Copyright © Zhengzhou TONGDING Machinery&Equipment Co., Ltd.Power by yisainuo