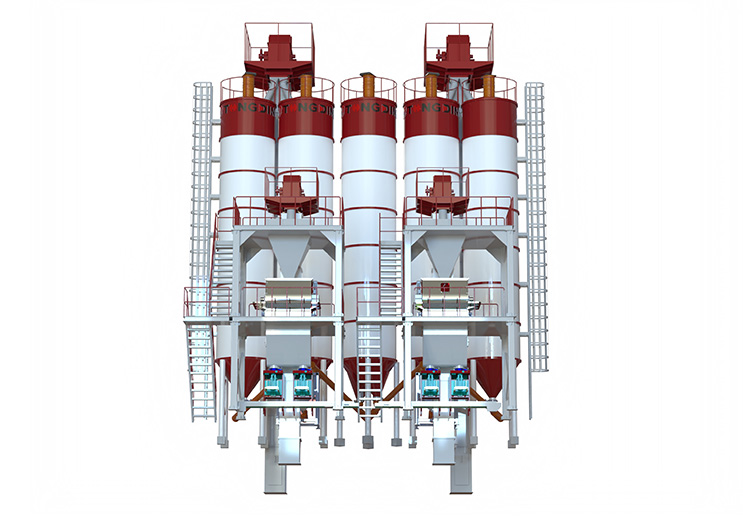

Capacity: 10-120 T/H

The production line of special mortar developed by tongding machinery is a production plan with low investment cost. The main application is exterior wall and interior wall putty, ceramic tile adhesive agent and other powder manufacturing which integrates the aggregate drying, automatic batching, non-gravity efficient mixer, finished product bagging.

E-mail :

info@tongdingmachinery.com1. The mixing efficiency is about 30% higher than that of the traditional twin shaft mixer.The dust emission concentration is less than 20mg/Nm³, and the noise at the factory boundary is less than 55dB.

2. Adopt easy installation and disassembly structure, simple operation, easy maintenance and repair.

Used for Masonry mortar, Plastering mortar(bottom), Floor mortar, Caulking agent mortar(black), Seaming agent mortar, Caulking agent mortar(white), Seaming agent mortar, Thermal mortar, Self-leveling mortar, Whitewashed plaster(bottom), Cement plaster mortar, External putty powder, etc.

Dry Mortar

Cementing Material

Putty Powder

Grouting Material

Masterbatch

Additive

Vitrified Microsphere

Hot Melt Marking Coating

Plastering Gypsum

| MODEL | TDSJ2 | TDSJ3 | TDSJ4 | TDSJ6 | TDSJ10 | Remark |

| CAPACITY(T/H) | 10-20 | 20-40 | 40-60 | 60-80 | 80-120 | |

| HOST MOTOR(kw) | 18.5 | 22 | 30 | 45 | 55 | |

| AGGREGATE SIZE(mm) | 0〜4.75 | 0〜4.75 | 0〜4.75 | 0〜4.75 | 0〜4.75 | |

| AGGREGATE SCALE(kg) | (200〜1000)±1% | (200〜1500)±1% | (200〜2000)±1% | (400〜3000)±1% | (400〜4000)±1% | customizable |

| CEMENT SCALE(kg) | (100-600)±1% | (100-700)±1% | (100-800)±1% | (200-1300)±1% | (200-1800)±1% | customizable |

| ADDITIVE SCALE(kg) | (5〜30)±0.5% | (10〜40)±1% | (10〜50)±0.5% | (10〜200)±0.5% | (10〜200)±0.5% | customizable |

The Triple cylinder rotary dryer is divided into the inner cylinder, the middle cylinder and the outer cylinder. high efficiency and energy saving.

The system uses the unique integrated container(gravity + bag) dust collector to achieve intelligent control of pulse ash removal, with the all environmental emissions less than 20mg/Nm³

Designed with unique VF feeding technologies to realize batching accuracy higher than requirements of industrial standards.

Combines advanced plow type mixer patented core technology and unique VF patented mixing technology to ensure high efficiency and energy saving by 25%, maximum mixing ratio: 1:10000, high wear resistance and long service life.

Valve port packaging machines are mainly divided into impeller packaging machine, air floating packing machine and pneumatic packaging machine.After the goods are filled, the products will squeeze the closed valve port from the inside to achieve the purpose of sealing.

Bulk packaging machine is an ideal equipment for the loading and shipping of powder materials in the building materials, metallurgy, coal and chemical industries.

Dry mortar mixing control cabinet can receipt more than 10 kinds of formula settings and automatically control batching, weighing and mixing. There are 2 kinds of control cabinets: industrial computer control cabinet and touch screen control cabinet. In contrast, the touch screen is more convenient to use.

Don't Hesitate Contact Us For Better Help & Services

E-mail :

info@tongdingmachinery.comTel / Whatsapp / Wechat :

+86 13673306161Fax :

+86 0371 63715718Copyright © Zhengzhou TONGDING Machinery&Equipment Co., Ltd.Power by yisainuo