Capacity: 1-10 T/H

Mini-type dry mortar mixing production line, which covers a small area, is cheap and easy to operate, is very suitable for small factories.

E-mail :

info@tongdingmachinery.comThis solution includes 6 procedures:

Artificial feeding →lifting material → mixing →two lifting of materials → finished product storage→weighing and packaging;

1). Artificial feeding: manual feeding of raw materials and additives into the mouth;

2). To enhance the material: and then through a hoist to lift the material to the mixer;

3). Mixing: mixing machine for the full mixing of materials, about 5-10 minutes;

4). The two lifting material: after the completion of the material, through the two lift, transport to the finished goods warehouse;

5). Finished warehouse: finished warehouse after receiving material, storage;

6). Weighing and packaging: through the outlet of the finished warehouse packaging machine for automatic weighing and packaging.

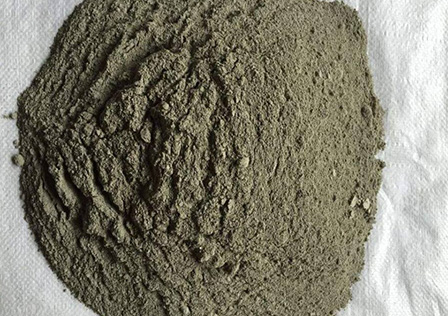

Used for Foundry sand, Crack Resistant Mortar, Plastering Mortar, Bonded Mortar, Decorative Mortar, Masonry Mortar, Gypsum Mortar

Dry Mortar

Cementing Material

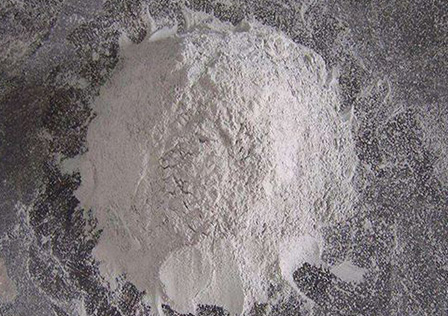

Putty Powder

Grouting Material

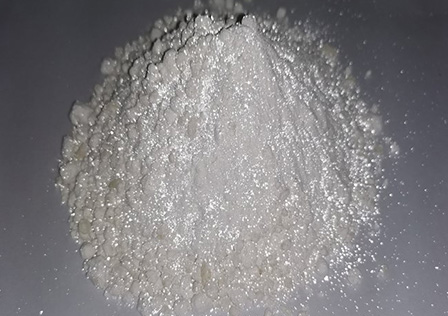

Masterbatch

Additive

Vitrified Microsphere

Hot Melt Marking Coating

Plastering Gypsum

| Model | Host Motor | Capacity(T/H) |

| MINI-1000 | 7.5 | 1-3 |

| MINI-2000 | 11 | 2-6 |

| MINI-3000 | 15 | 3-9 |

| MINI-5000 | 22 | 5-10 |

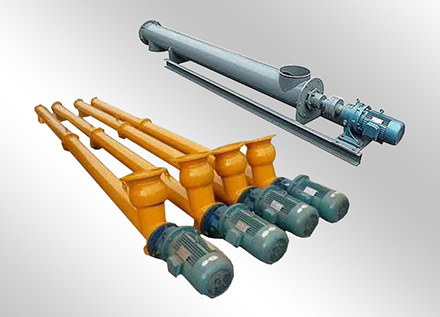

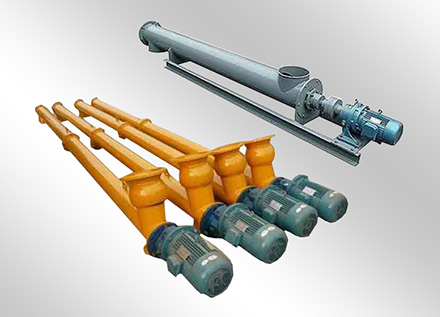

Feed raw materials and additives though the feeding port into the 1st screw convey.

Conveying materials to the mixer.

1.The spiral blade adopts wear-resistant steel;

2. The patent sealing device to prevent the bearings into the dust.

Completely mix the raw materials and additives into ideal mixing effect.

1. The spiral belt wear resistant steel, has a long service life;

2. It is backed by wheel drive settings, to prevent shaft breaking;

3. The motor reducer adopts direct type, stable quality, energy saving and environmental protection.

Conveying materials to the finished product hopper.

1. The spiral blade adopts wear-resistant steel;

2. The patent sealing device to prevent the bearings into the dust.

Collect dust more effectively.

Separation of impurities.

To store the finished product, and equipped with automatic vibration device to ensure that materials can enter the packaging system quickly.

Intelligently pack the finished products in bags.

1.Valve bag packing machine;

2.Open bag packing machine;

3.Ton bag packing machine;

4.Bulk packing machine.

Don't Hesitate Contact Us For Better Help & Services

E-mail :

info@tongdingmachinery.comTel / Whatsapp / Wechat :

+86 13673306161Fax :

+86 0371 63715718Copyright © Zhengzhou TONGDING Machinery&Equipment Co., Ltd.Power by yisainuo