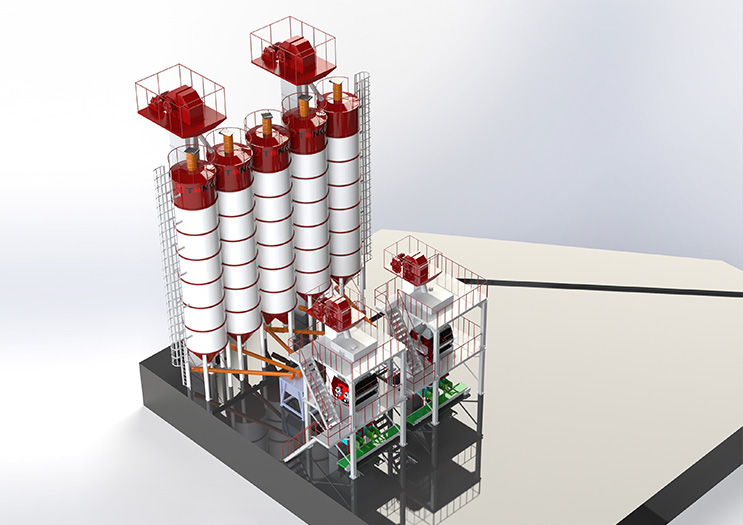

Capacity: 10-120 T/H

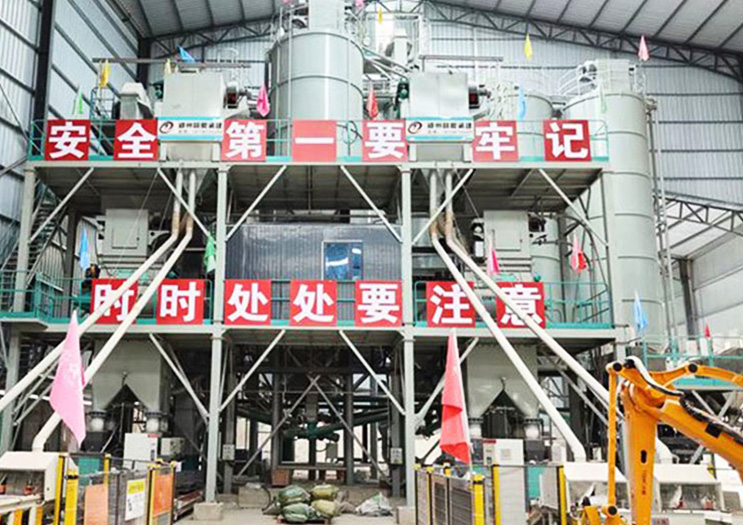

The new generation of efficient gypsum mortar production line supports the large-scale batch continuous production of light gypsum mortar and heavy gypsum mortar. The production process of the line is stable and efficient, and the production environment is clean and friendly. Various materials such as gypsum powder, glass beads, sand, calcium powder, additives can be fully mixed and uniform in a short time. The mixing action is soft and efficient, and the properties of various materials such as glass beads are stable and consistent, so as to ensure that the functional advantages of gypsum mortar are perfectly presented in the later construction process.

E-mail :

info@tongdingmachinery.com1. Gypsum mortar is a new type of wall plastering material, which is based on semi-aqueous gypsum and mixed with inorganic materials.

2. Gypsum based mortar has the advantages of crack resistance, heat insulation, sound insulation, automatic adjustment of indoor humidity, strong adhesion, easy construction and fast speed.

Used for Masonry mortar, Plastering mortar(bottom), Floor mortar, Caulking agent mortar(black), Seaming agent mortar, Caulking agent mortar(white), Seaming agent mortar, Thermal mortar, Self-leveling mortar, Whitewashed plaster(bottom), Cement plaster mortar, External putty powder, etc.

Dry Mortar

Cementing Material

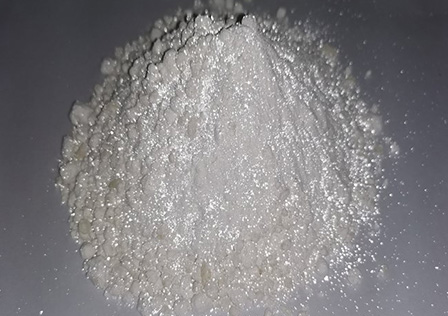

Putty Powder

Grouting Material

Masterbatch

Additive

Vitrified Microsphere

Hot Melt Marking Coating

Plastering Gypsum

| MODEL | TDSJ2 | TDSJ3 | TDSJ4 | TDSJ6 | TDSJ10 | Remark |

| CAPACITY(T/H) | 10-20 | 20-40 | 40-60 | 60-80 | 80-120 | |

| HOST MOTOR(kw) | 18.5 | 22 | 30 | 45 | 55 | |

| AGGREGATE SIZE(mm) | 0〜4.75 | 0〜4.75 | 0〜4.75 | 0〜4.75 | 0〜4.75 | |

| AGGREGATE SCALE(kg) | (200〜1000)±1% | (200〜1500)±1% | (200〜2000)±1% | (400〜3000)±1% | (400〜4000)±1% | customizable |

| CEMENT SCALE(kg) | (100-600)±1% | (100-700)±1% | (100-800)±1% | (200-1300)±1% | (200-1800)±1% | customizable |

| ADDITIVE SCALE(kg) | (5〜30)±0.5% | (10〜40)±1% | (10〜50)±0.5% | (10〜200)±0.5% | (10〜200)±0.5% | customizable |

The Triple cylinder rotary dryer is divided into the inner cylinder, the middle cylinder and the outer cylinder. high efficiency and energy saving.

The system uses the unique integrated container(gravity + bag) dust collector to achieve intelligent control of pulse ash removal, with the all environmental emissions less than 20mg/Nm³

Designed with unique VF feeding technologies to realize batching accuracy higher than requirements of industrial standards.

Combines advanced plow type mixer patented core technology and unique VF patented mixing technology to ensure high efficiency and energy saving by 25%, maximum mixing ratio: 1:10000, high wear resistance and long service life.

Valve port packaging machines are mainly divided into impeller packaging machine, air floating packing machine and pneumatic packaging machine.After the goods are filled, the products will squeeze the closed valve port from the inside to achieve the purpose of sealing.

Bulk packaging machine is an ideal equipment for the loading and shipping of powder materials in the building materials, metallurgy, coal and chemical industries.

Dry mortar mixing control cabinet can receipt more than 10 kinds of formula settings and automatically control batching, weighing and mixing. There are 2 kinds of control cabinets: industrial computer control cabinet and touch screen control cabinet. In contrast, the touch screen is more convenient to use.

Don't Hesitate Contact Us For Better Help & Services

E-mail :

info@tongdingmachinery.comTel / Whatsapp / Wechat :

+86 13673306161Fax :

+86 0371 63715718Copyright © Zhengzhou TONGDING Machinery&Equipment Co., Ltd.Power by yisainuo